Pre-programmed Laptop or computer computer software operating a CNC machine would make this possible via the opportunity to convert any style and design into a concluded merchandise.

These developments will help the production of more intricate molds with shorter turnaround periods, driving efficiency in manufacturing processes throughout many sectors.

The historical past of CNC machines dates back into the forties and 1950s when the initial numerically controlled (NC) machines were being created. These early machines used punched tape to regulate the movement of machine tools.

The aerospace industry has an extended-shared heritage with CNC machining. The machining of metal aircraft factors occurs at the very best degree of precision.

Over the trip, Bredikhin frequented four of the Taiwanese machine tool suppliers whose equipment he later on imported, in addition to 1 other, Based on given that-taken out images and posts shared to Fb and Instagram. At 3 in the amenities, he and Yu are pictured providing a thumbs up.

CNC Routers: CNC routers are broadly acknowledged for easily cutting smooth materials which include Wooden, plastics, and aluminium to generate intricate styles.

The primary costs linked to CNC machining might be grouped into machining time, start out-up costs, content charges, and feature expenses. To lessen fees you need to comprehend the effects of these components on Price tag.

CNC machines have been critical within the semiconductor industry Used industrial CNC machines Because the nineteen eighties, enabling the production of more and more lesser and even more complex microchips.

Bead Blasting: A surface area treatment method course of action to acquire a certain degree of cleanliness and distinct roughness on the surface area in the workpiece. The floor immediately after sandblasting is boring and matt.

For starters, good quality precision machining needs a superior-conclusion cutting tool effective at getting rid of the fabric very carefully to match the desired item Proportions.

Industries will gain from bigger precision, efficiency, and sustainability, ensuring that CNC machines stay a cornerstone of modern manufacturing. No matter whether you’re linked to mass production or custom machining, understanding the function of CNC machines inside your industry will allow you to keep competitive in an increasingly complex and dynamic marketplace.

You will find general input gadgets for example punch tape viewers, and magnetic tape audience. The CNC Machine’s driving procedure, which includes electronic equipment circuits, generate motors, and ball guide screws, along with the suggestions technique, is constantly checking the place and speed of the cutting tools.

CNC stands for Pc Numerical Manage. The CNC machining procedure is really a manufacturing process that creates the ultimate portion by eliminating materials employing a cutting tool. There are lots of differing kinds of CNC machines with a lot of cutting tool choices for a range of Careers and applications.

For moveable machining operations involving three to various axes, CNC machines are usually employed. Laptop or computer software package is usually used to generate programming or work Recommendations, which can be enter right into CNC machines.

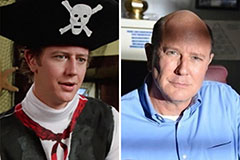

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!